CNC Turning Services

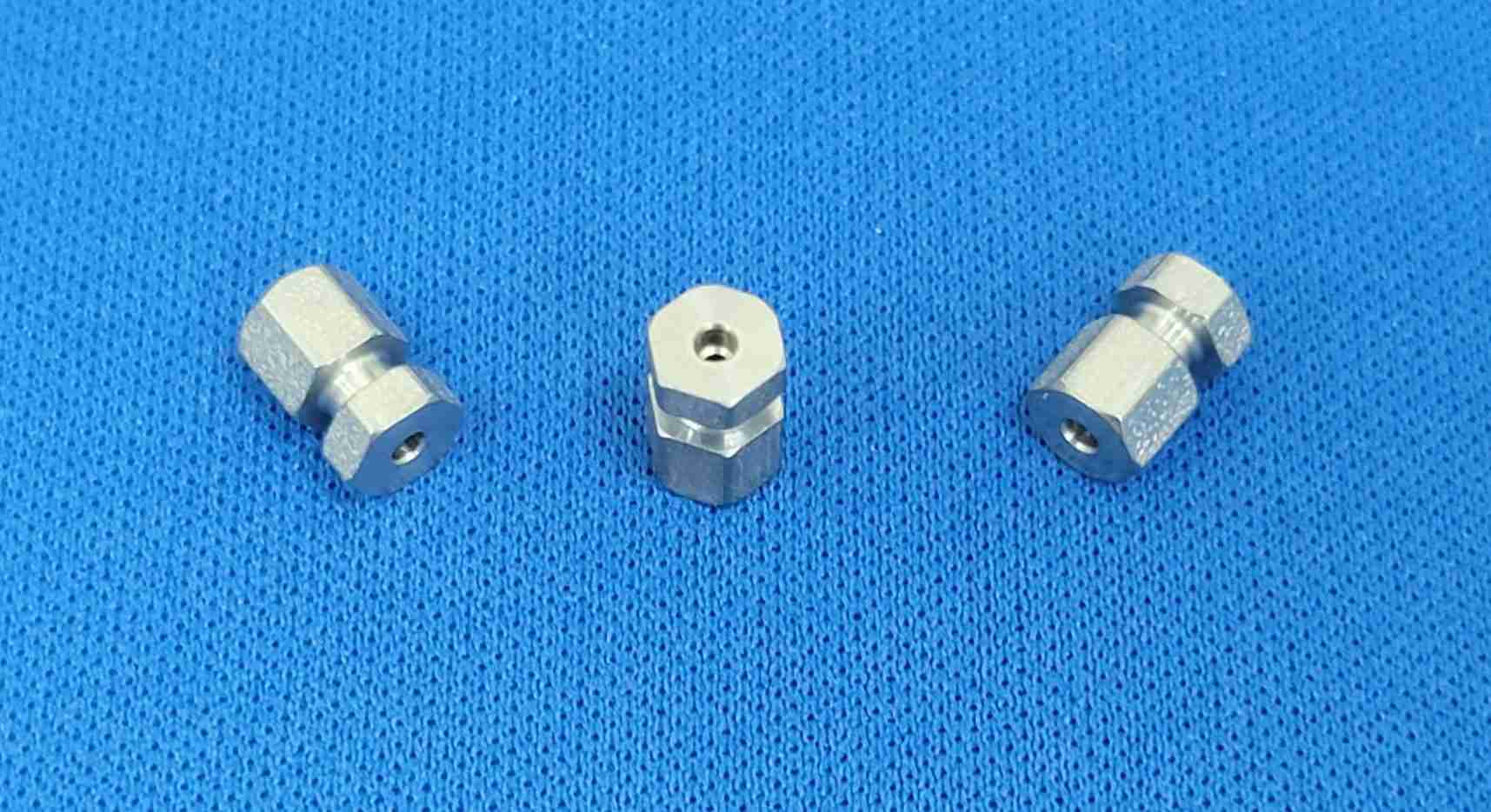

CNC Turned Parts: Rapid Prototyping And Mass Production

We offer custom CNC turning services for design prototyping and large-scale complex manufacturing requirements.

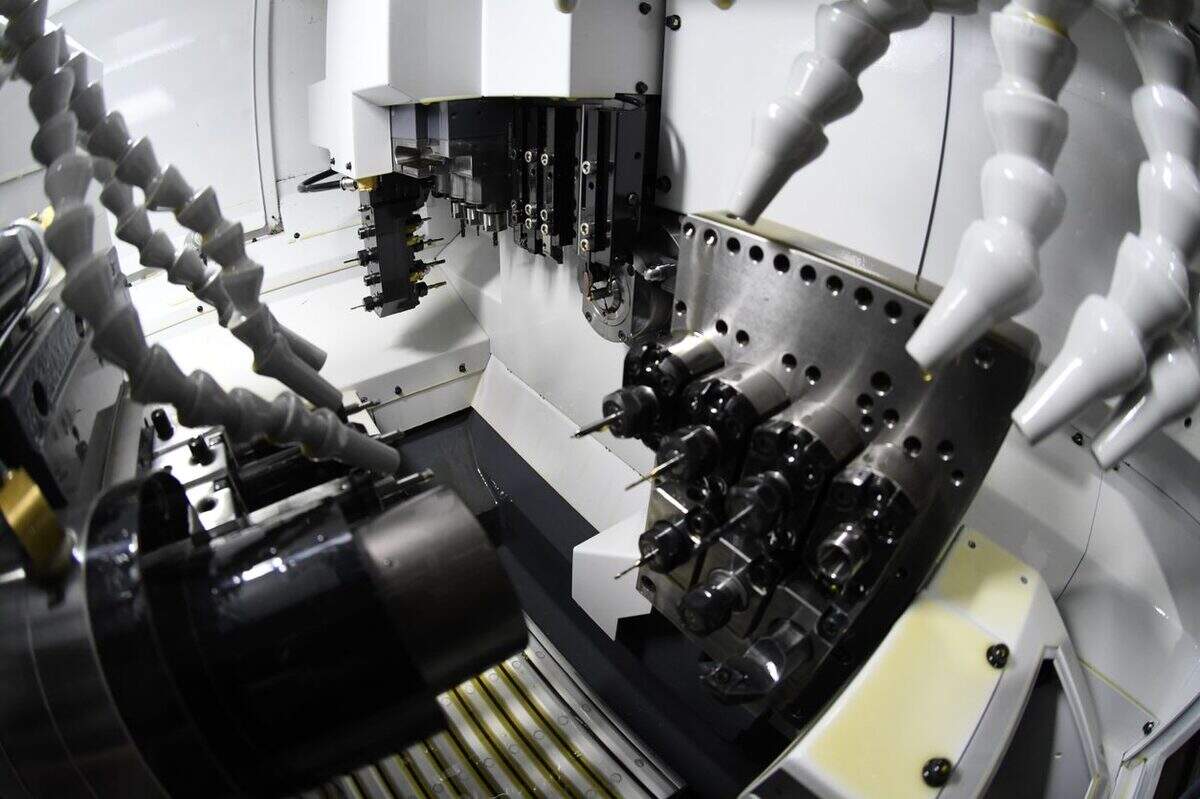

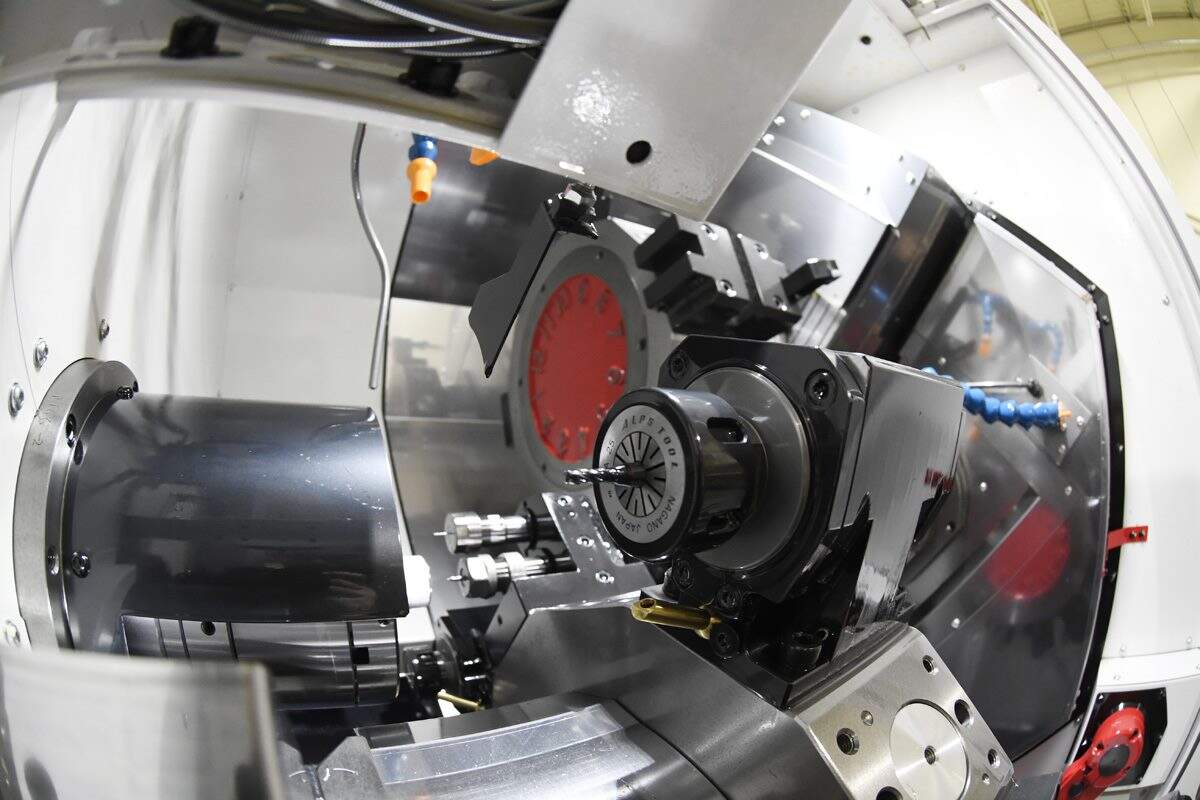

Our extensive machine shop includes 2-axis, C-axis, Y-axis and Swiss-type (up to 9-axis) manual and CNC lathe machines. They can undertake projects of any size and complexity. Our CNC turning centers produce top-quality parts using 3D CAD files, DXF files, flat pattern drawings, and CAD-neutral files.

Our machinists set up programmable logic and NC codes for controls by keeping your end goals of precision in mind. Through our partnership, you get high-quality physical prototypes by transforming your design concepts using our advanced CNC lathe turning centers.

Macfab’s CNC Turning Capabilities

At Macfab, we offer CNC turning services for various grades of aluminum, copper, steel, titanium, zinc, and other carbon fibres. We primarily engage with biomedical research industries, aerospace, research, defence, and environmental industries needing high-precision manufacturing. We offer tolerances up to 0.0001 inches or 1/4th of a human hair’s diameter.

Our turning centers can handle jobs of diameters between 1 inch and 18 inches and lengths between 9 inches and 48 inches. For mass production, we also undertake turning jobs with diameters as small as 0.47 inches, a length of 8 inches, and a tolerance range of 20 µm.

Our expert machinists are trained to accurately coordinate the spindles, turrets, and chuck involved with fixed workpieces to deliver the highest machining quality. Our large facility offers various CNC programmable lathes, Swiss-turn style lathes, 8-axis dual turret lathes with variable velocities, and precision gang tool lathes.