The Precision of 5-Axis CNC Machining in Advanced Geometries

5-axis machining is an advanced form of CNC (Computer Numerical Control) machining that allows manufacturers to create intricate and complex parts by moving a tool or workpiece in five different axes simultaneously. This approach differs from traditional 3-axis machining, which operates along three linear axes (X, Y, and Z).

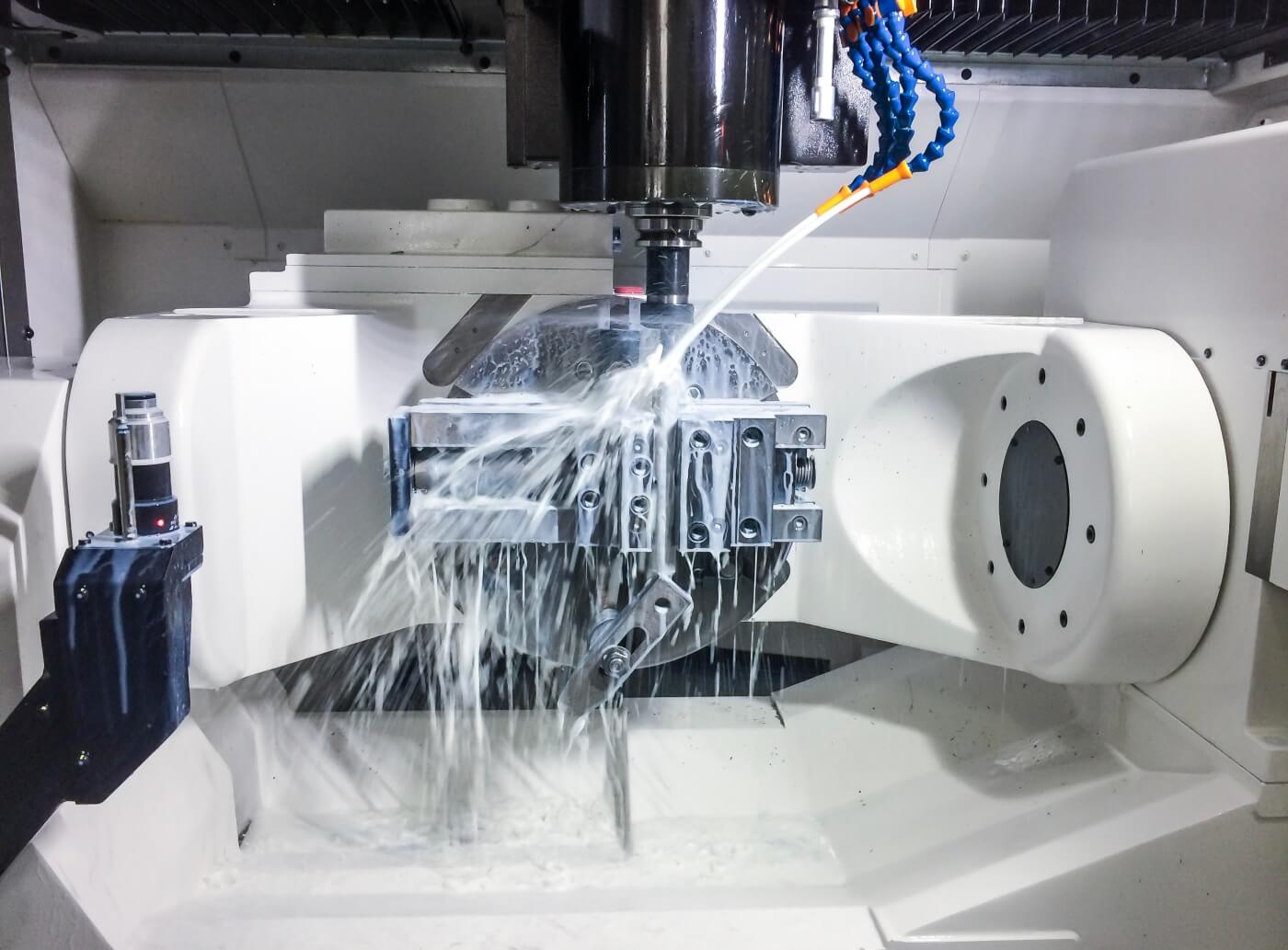

In 5-axis machining, two additional rotary axes rotate the table or the cutting tool, with common configurations including tilting the tool head or rotating the workpiece. This feature enables more dynamic and versatile movement, allowing the machining of complex geometries and detailed parts without needing multiple setups or repositioning the workpiece more than once or twice.

In the aerospace industry, medical devices, and the automotive sector, the ability to machine high-precision, intricate parts efficiently and effectively is essential. 5-axis machining’s flexibility and efficiency make it invaluable in these fields.

Unparalleled Precision and Efficiency

Machine shops with 5-axis machining centers offer high precision and accuracy by allowing cutting tools to approach a workpiece from multiple angles, creating complex geometries in fewer setups. The flexibility and high speeds help reduce cycle times and improve accuracy by minimizing the need for repositioning.

A fundamental advantage is the capability to machine five sides of a part in a single setup, except the final side, ensuring the accurate positioning of all surfaces with respect to the datums.

The Future Role of AI in Achieving Advanced Geometries

Artificial intelligence (AI) could enhance machining workflows by analyzing vast data to recommend optimal tools and cutting parameters, ensuring efficiency and precision. It will aid estimating departments by accurately predicting cycle times and helping in cost assessment and planning.

Additionally, AI-powered software will streamline CNC programming, automatically generating paths based on part designs and material properties. It will minimize human error, speed up development, and maximize resource utilization.

AI boosts efficiency for skilled machinists by automating time-consuming tasks like toolpath generation and optimizing cutting parameters. AI-driven systems can rapidly analyze design files and suggest optimized machining processes, significantly reducing programming time and leading to increased machine uptime and productivity.

Looking Forward

Advancements like simultaneous 5-axis machining and AI are reshaping the future of CNC machining, allowing companies to tackle complex geometries (and challenging components) quickly and efficiently. These technologies enhance tool selection, optimize workflows, and improve precision, leading to faster production times and higher-quality, complex parts.

By reducing programming time and minimizing errors, AI empowers machinists to handle intricate designs that were previously daunting. This evolution boosts productivity and positions manufacturers to remain competitive in an increasingly complicated manufacturing landscape.

Contact Us for Expert Advice

Contact Macfab Manufacturing today to discover how our advanced services can support your complex projects. Our expertise in 5-axis machining will improve your production capabilities with precision and efficiency.

Schedule a consultation with our team to explore tailored solutions that meet your unique needs. Let us help you leverage cutting-edge technology to improve your production processes and deliver superior results.