Harnessing Hybrid Production: The Synergy of Additive Manufacturing and CNC Machining

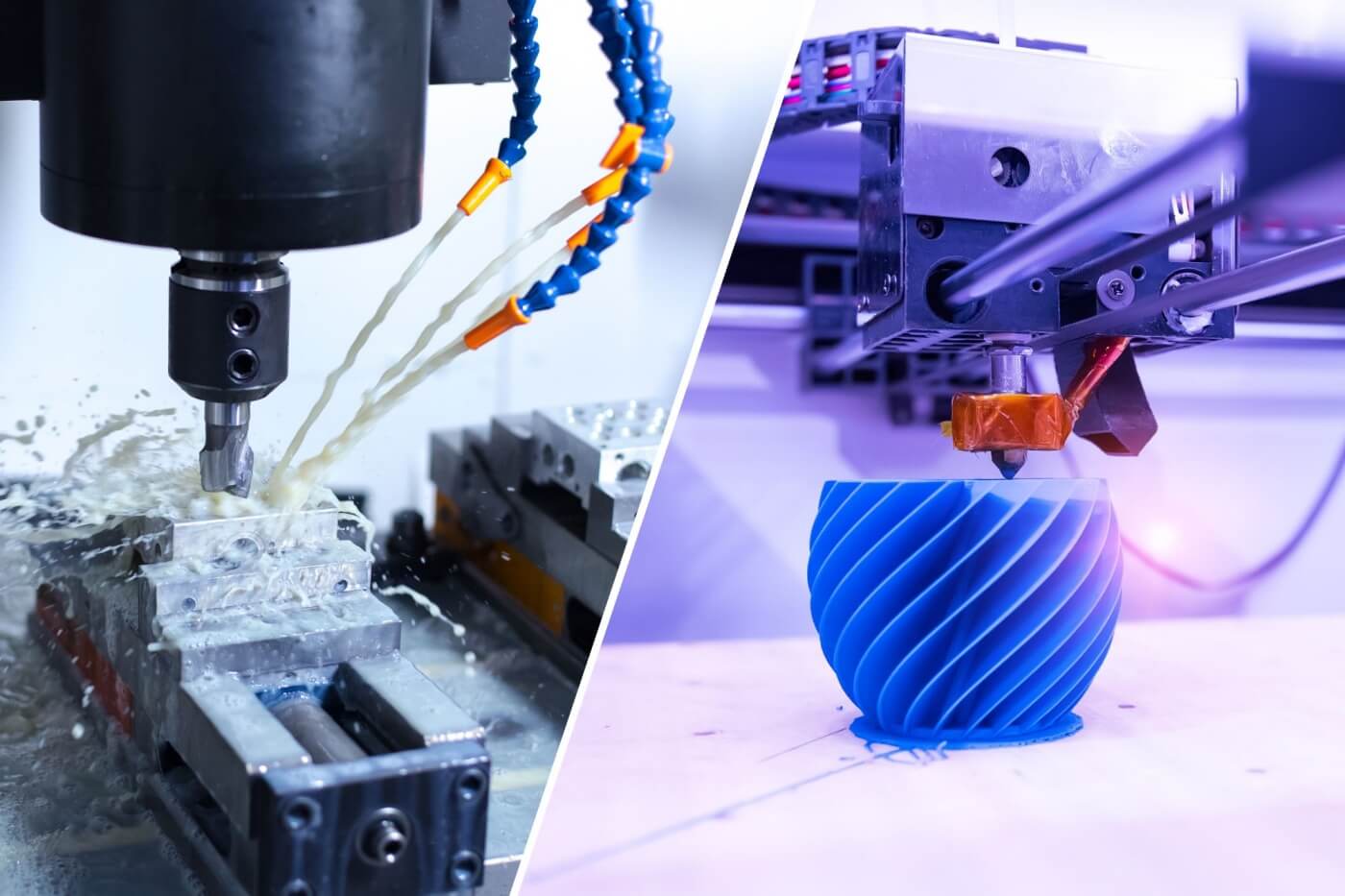

Additive and subtractive manufacturing are the two primary approaches used in today’s modern production environments. Additive manufacturing (AM), or 3D printing, builds components layer by layer and is ideal for creating intricate geometries, internal structures, or multi-material regions.

On the other hand, subtractive manufacturing (SM), like CNC machining, removes material from a solid block, achieving tight tolerances and smooth finishes. Hybrid systems integrate these methods either in a single machine or across multiple machines in a coordinated workflow.

Understanding the Processes: AM and SM

AM creates three-dimensional objects directly from a digital model, typically a CAD (computer-aided design) file. The process works by depositing material under computer control and bonding each new layer to the one below it until the object is complete. Plastics, metals, ceramics, and resins are all common materials used in 3D printing.

During SM, the material is removed from a solid block, bar, or rod to create a part or component. This removal occurs through various controlled machining techniques such as milling, drilling, turning, grinding, or boring, often using CNC machines for high precision and automation.

Hybrid manufacturing integrates additive and subtractive processes to maximize the strengths of each.

The Hybrid Manufacturing Techniques

Hybrid manufacturing combines additive and subtractive techniques, often using the same machine. Hybrid machines typically consist of a machine tool, such as a milling machine, with a directed energy deposition (DED) head to deposit wire or metal powder. Other manufacturing systems may combine machining with powder-bed fusion (PBF) or material extrusion. These one-step hybrid machines can perform subtractive and additive manufacturing in a single process.

In multi-machine workflows—like those used at Macfab—parts are transferred between dedicated 3D printers and CNC machines. Here, additive components are strategically designed with excess material in critical areas specifically for post-processing. This enables tighter tolerances and improved surface finishes during CNC machining. By partnering with OEMs and additive manufacturing shops, Macfab post-machines AM parts to achieve results that go beyond what additive techniques can accomplish alone.

The Benefits of a Hybrid Approach

Hybrid manufacturing enables the production of parts with intricate shapes and features that are difficult or impossible to create with traditional methods. CNC machining achieves tight tolerances and high-quality surface finishes on parts that were initially 3D printed.

Using a combination of additive and subtractive processes, manufacturers can minimize material waste compared to traditional subtractive manufacturing alone. By combining the speed of 3D printing with the precision of CNC machining, hybrid manufacturing results in faster production times, which brings parts to the market faster.

In some cases, hybrid manufacturing can be more cost-effective than traditional methods, especially for complex parts.

The Future of Manufacturing: Combining Flexibility with Precision

When companies combine additive and subtractive manufacturing processes into a hybrid operation, the range of benefits for future machining work is impressive. The print-and-machine process leverages both operations’ strengths while minimizing their limitations.

For instance, hybrid manufacturing can combine different materials within a single part, taking advantage of each unique property and enabling the production of components with tailored mechanical or thermal properties.

Hybrid machines allow for the creation of complex geometries and internal features that are difficult to achieve with subtractive methods alone. Additive manufacturing can build intricate structures, while subtractive processes can create critical surface finishes and dimensions.

Combining CNC machining with a 3D printer can accelerate prototyping and low-volume production by eliminating the need to transfer parts in the machine shop.

Hybrid manufacturing technology could advance a company’s manufacturing processes and product offerings, making them more competitive and capable in various industries.

Unlocking the Full Potential of Hybrid Manufacturing

Hybrid manufacturing isn’t just a trend—it’s a strategic evolution in production. By uniting the precision and finish of CNC machining with the design freedom and material efficiency of additive manufacturing, companies can push past the limitations of traditional methods.

This approach opens new possibilities for innovation, accelerates product development, and delivers higher-quality parts with greater speed and flexibility. As manufacturing demands grow more complex and competitive, hybrid production offers a smart, scalable solution. Forward-thinking manufacturers who embrace this synergy will be better positioned to meet the challenges of tomorrow and lead the industry into the future.